Protect your systems from electromagnetic interference with EMC cable glands!

If electromagnetic interference is affecting the normal operation of your systems, Bimed EMC cable glands are the ideal solution. They provide long-lasting protection, easy installation, and resistance to harsh conditions.

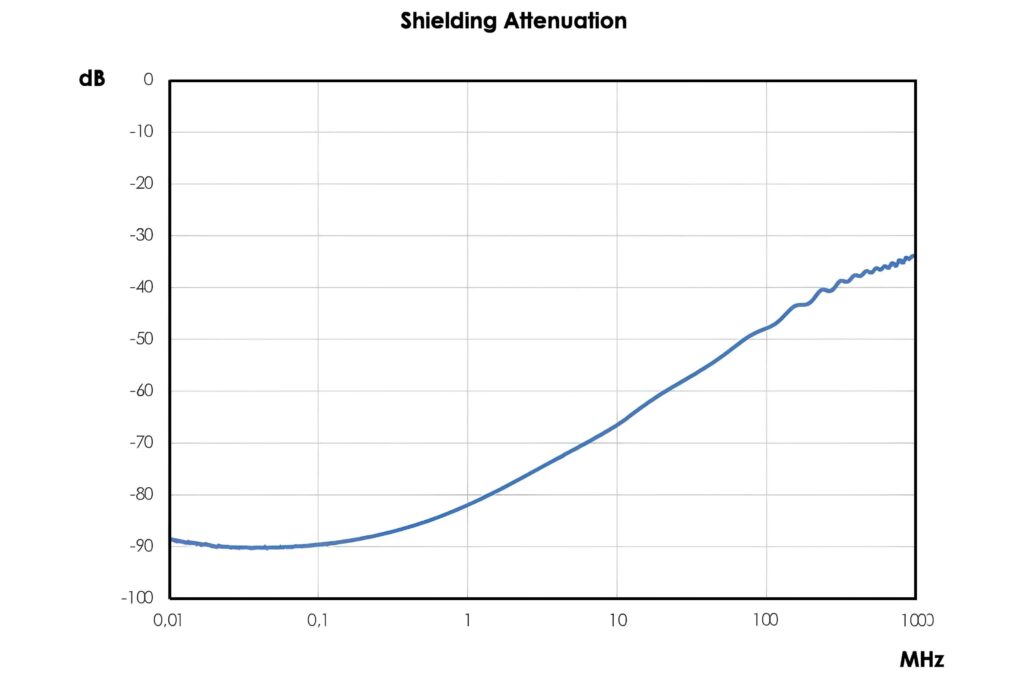

Bimed EMC cable glands are engineered to protect electrical cables from electromagnetic interference (EMI). Thanks to the EMC component that enhances contact with the cable, these cable glands ensure continuous operation of the equipment. Equipped with an advanced shielding system, they reduce disturbances and improve the performance and longevity of devices. The shielding attenuation indicates the effectiveness of the shielding in blocking EMI, increasing reliability and reducing maintenance costs.

Bimed EMC cable glands are ideal for a wide range of applications, including:

Electric Mobility

• PDU, Generator, DC Charging

Automation

• Critical EMI Sensors, Semiconductor Production Machines

Railway Industry

• Generator, Speed Sensors, General Electrical Distribution Enclosures

Telecommunications

• 5G Enclosures

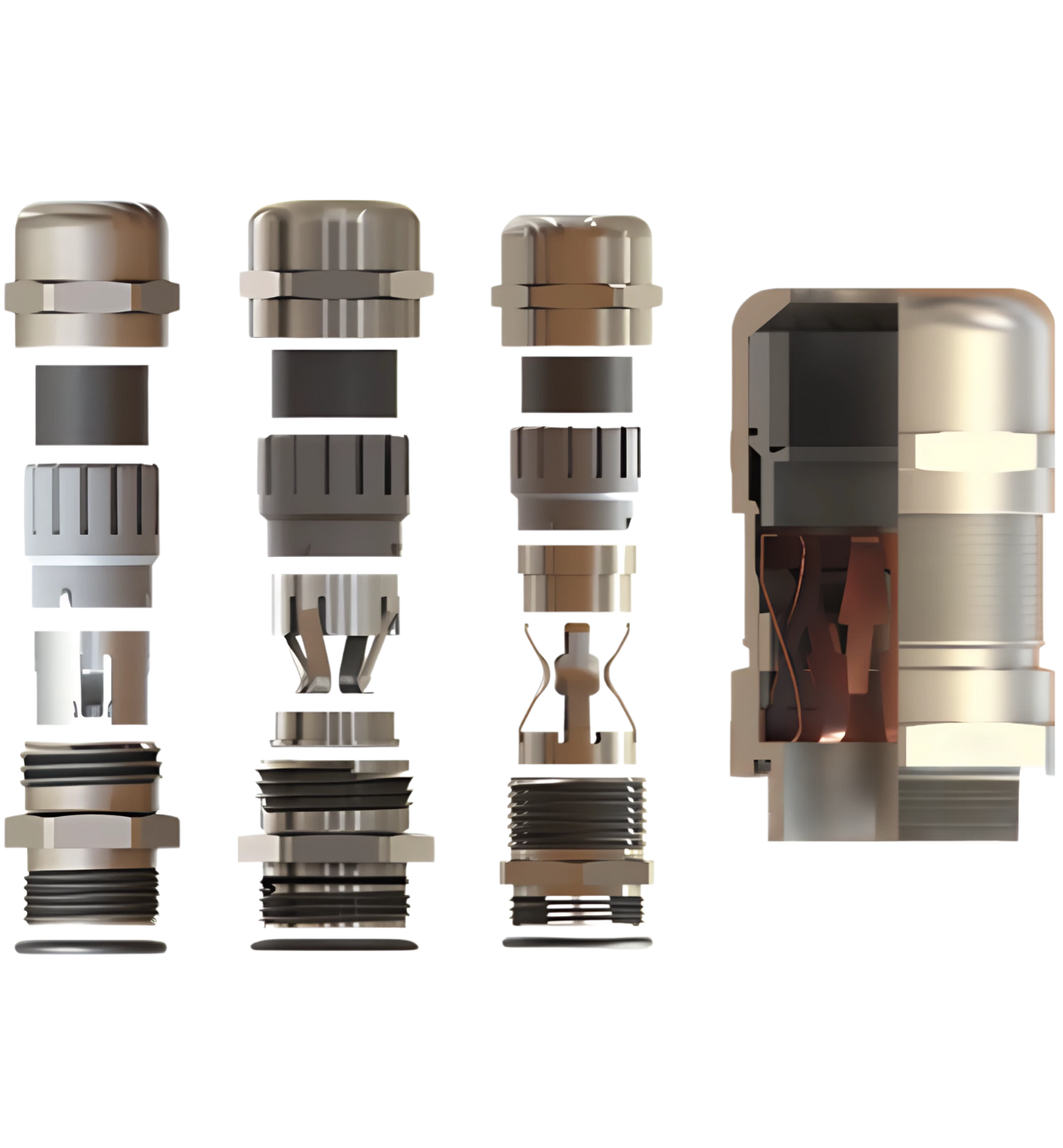

Available in 4 generations, each with specific features, to always provide excellent protection against electromagnetic interference.

Ideal for environments that require basic EMC shielding, ensured by effective contact between the cable braid and the spring, with a material that guarantees adequate protection.

Why choose them:

- No disassembly required for EMC contact.

- Shorter assembly times for quick installation.

- Compatible with copper tape application for additional shielding in case of more stringent EMC requirements.

Perfect for industrial environments where EMC performance is important, but there are no intense vibrations or high loads.

Why choose them:

- All the benefits of generation 2.

- Advanced protection: the spring contact design ensures effective sealing and preserves cable shielding..

- Reliability: high tensile strength and protection against electromagnetic interference, with long operational life.

The ideal choice for industrial environments with intense vibrations, high electromagnetic interference, and heavy loads.

Why choose them:

- All the benefits of generation 3.

- Improved EMC performance thanks to the reverse spring, which reduces the distance between the strain relief and contact, enhancing effectiveness in case of vibrations.

- Long-term reliability: reduced contact resistance due to large contact surfaces.

The increased mechanical strength makes EMC-SA cable glands more suitable for demanding applications, such as those exposed to vibrations.

The new design of the EMC component has increased the number of contacts between the shielding and the cable gland, thereby improving contact performance.

Why choose them:

- Stable contact: double EMC spring for a secure and durable connection.

- Suitable for high currents: greater number of contacts for optimal conduction on the shielding.

- Cable sheath protection: system with open contact blades for enhanced flexibility.

High Load Resistance

Stable contact with the cable shielding, reducing derating even under high current loads.

Excellent EMC Shielding

Effective protection against electromagnetic interference for stable and safe operation.

Certifications

EMC cable glands comply with international standards such as VDE, UL, and DNV, and are engineered according to DIN 62444/50262.

High-Quality Strain Relief

The cable remains securely in place, even under vibration.

Resistance

Water- and dust-resistant to ensure optimal performance in harsh environments.

Easy Installation

Simple, quick installation helps reduce working time and overall costs.

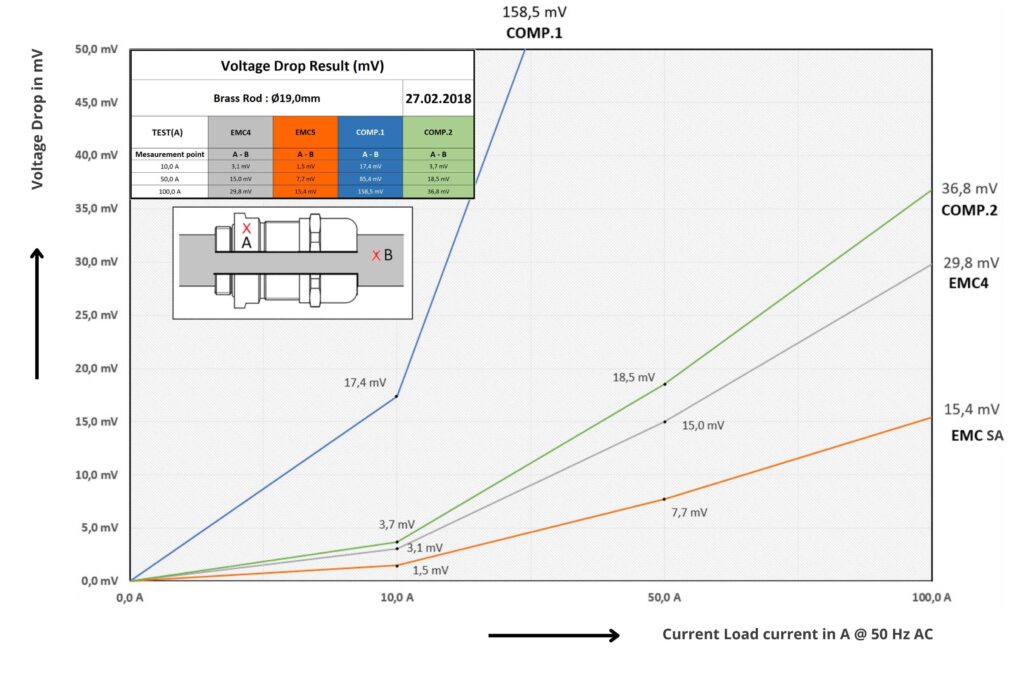

Voltage Drop in EMC Cable Glands

The EMC-SA contacts are thicker than those in the EMC3 and EMC4 models.

This increased robustness helps reduce ohmic resistance at the contact area, resulting in lower voltage drop and less heat dissipation.

The duplication of contacts ensures wider coverage of the cable braid, significantly enhancing EMC shielding, especially at high frequencies.

Compared to standard cable glands (COMP1 and COMP2), EMC-SA models offer significantly better EMC performance, both in terms of electrical continuity and shielding efficiency at high frequencies.

![NECTOGROUP | Join Innovation [EN] Logo](https://www.nectogroup.com/en/wp-content/uploads/2018/09/logo_nectogroup.png)

![NECTOGROUP | Join Innovation [EN] Logo](https://www.nectogroup.com/en/wp-content/uploads/2018/09/logo_nectogroup_sticky.png)